Expansion at Schumacher in Würselen: A new warehouse with the latest technology

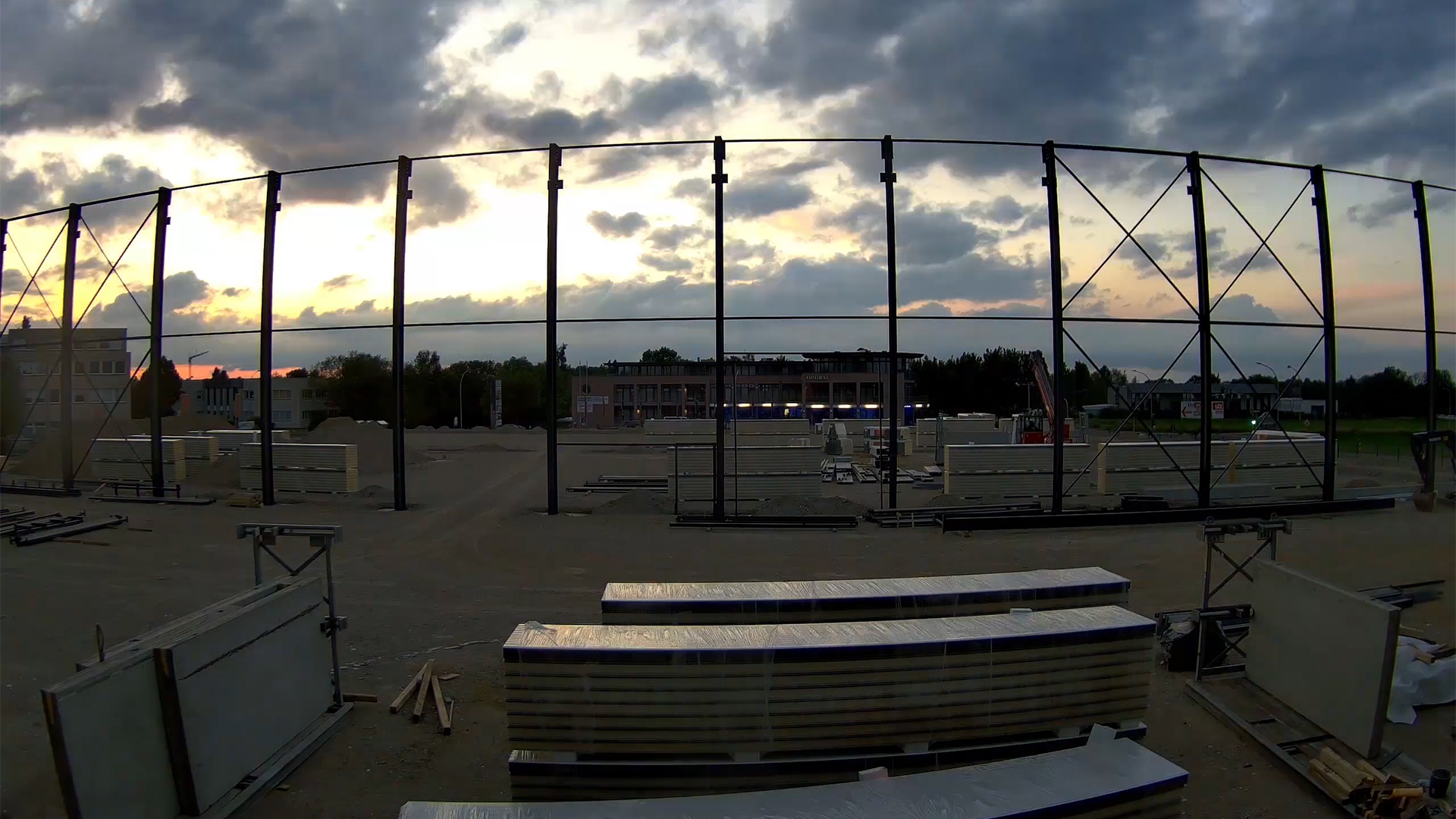

A groundbreaking expansion in our infrastructure is imminent and will catapult the Schumacher Group to a new level of efficiency and capacity. The brand new warehouse is an impressive technological feat and a symbol of our commitment to innovation and customer satisfaction.

The hall extends over an impressive 10,000 square meters and is equipped with the latest temperature-controlled storage space. With a capacity of over 25,000 pallet spaces and generous staging areas, the warehouse is optimally prepared for the challenges of dynamic logistics operations. Thanks to the nine loading gates, a smooth flow of goods is guaranteed, which further optimizes customer service.

An outstanding feature of this new system are the four electric mobile racking systems, supplied by the renowned company Jungheinrich, which make the storage and access to goods even more efficient. These state-of-the-art systems create flexible and efficient use of available space by allowing pallets to be positioned quickly and precisely. The result is an optimized warehouse space that allows more goods to be stored while making access and picking easier.

In addition, a separate storage area will be set up for picking to speed up the order fulfillment process and improve accuracy. This is crucial in an ever-changing market environment where flexibility and responsiveness to customer requests are paramount.

But not only the storage capacities are being expanded, the working conditions for the employees are also being significantly improved. New offices and a modern social area provide a pleasant working environment that promotes employee productivity and well-being.

In a clear commitment to sustainability, the company’s solar system was expanded to further reduce its ecological footprint. Installing temperature monitoring, alarm systems, sprinkler systems and full network coverage with WiFi not only ensures the safety of goods, but also smooth communication and monitoring of the entire operation.

Another focus was on modernizing the equipment fleet. The introduction of the latest generation of forklifts, including high rack forklifts, dedicated order picking equipment, all with lithium technology, promises optimal performance and efficiency in handling goods.

In order to meet the ever-growing requirements, the warehouse management system was also completely overhauled. With new hardware such as scanners and forklift terminals that enable employees to manage inventory precisely and efficiently, Schumacher is now optimally prepared for the future.

Overall, the new warehouse marks a significant milestone in the development of our group of companies. By combining state-of-the-art technology, optimized workflows and a clear focus on customer satisfaction, we are setting a new standard in the logistics industry and cementing its position as a pioneer in this area.