With more than 20 years of experience in co-packing, we guarantee the smooth implementation of all requirements and specifications in order to produce optimally, taking into account all food hygiene regulations. Food safety and food defense are our top priorities so that our customers have the best possible quality.

Co-Packing by Schumacher

Services of the co-packing by Schumacher

- Inventory management across all process stages

- Packaging logistics

- Complicated packaging possible due to manual production

- Packaging of the articles according to customer specifications, taking into account batch and shelf life specifications

- Complete traceability

- Transfer to the finished goods inventory and / or preparation for loading

- Limited help for capacity utilization

- Interim storage of the palletized individual items (semi-finished products etc.) and the corresponding packaging materials

Modern equipment

With increasing technology, “Co-Packing by Schumacher” is opening a new chapter of further development and professionalization.

With our modern equipment, such as assembly lines, automatic case sealers, label dispenser systems and a fully automatic bagging machine, we guarantee even more efficient production processes in multi-shift operation and, in particular, attractive pricing with rising wage costs to be expected in the future.

In trusting cooperation with our customers we will take the next steps towards the future.

Schumacher hygiene lock

The Schumacher hygiene lock serves the purpose of avoiding contamination in our production area and is the basis of our personal hygiene.

The basic equipment of our hygiene lock includes, among other things, sensor-controlled hand washing and hand disinfection devices, which only allow access by means of hand disinfection and personal control by fingerprint at turnstiles.

Advantages of co-packing by Schumacher

- Years of experience

- Focus on perfect quality inspection processes and quality management

- Close cooperation with our customers

- The close proximity enables smooth cooperation with the warehouse, production and planning

- Combination offers possible: packaging, warehousing, sales

- Special offers in the low season

- Processes can be designed according to customer requirements (additional quality inspection and similar)

- Outsourcing of work steps such as planning, delivery, contact with suppliers

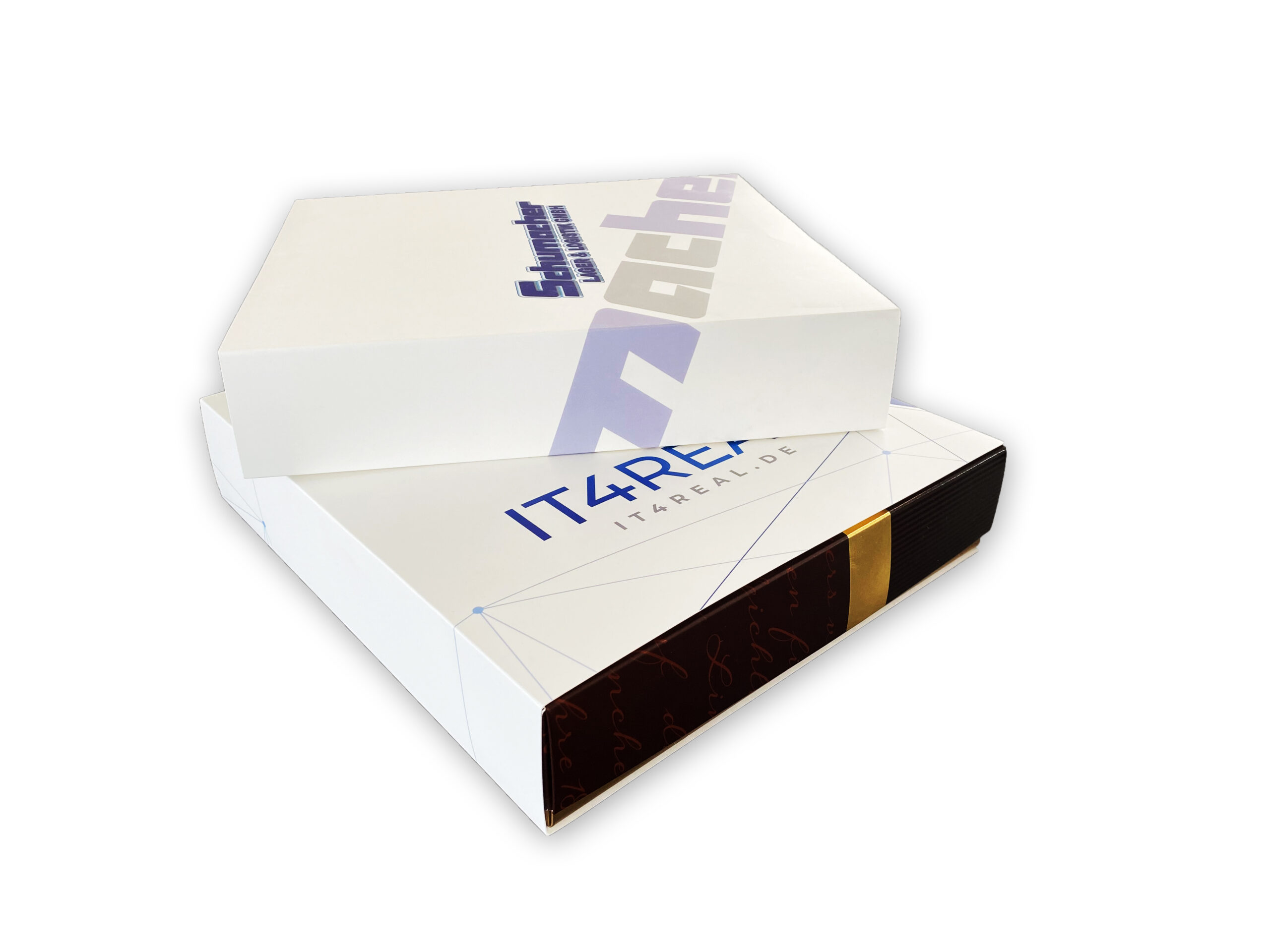

Examples of co-packaging by Schumacher

- Equipping advent calendars

- Attachment of cards, stickers, gift bows and similar

- Manufacture of blister cards of various sizes

- Display construction and assembly on roller conveyors

- Label attachment

- Assemble and fill folding boxes of all sizes

- Assemble pillow packs and gift sets and pack them ready for dispatch

- Montage of mailing folders

- All individual packaging possible (if food is in primary packaging)

- Slipcase for chocolate bars, chocolate candy etc.

- Even small quantities possible

- Filling assortment boxes

- Bags (mixed / universal) both hand and machine made

- Repackaging of large packaging in individual packaging or vice versa

- Fill all types of goods packages and boxes

- and much more